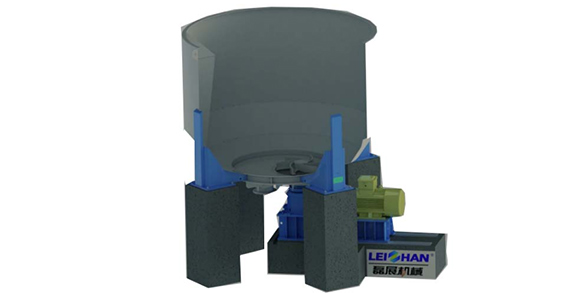

Eccentric Pulper for Making Pulp

Unlike traditional pulpers, which utilize a vertical or horizontal configuration, the eccentric pulper employs a unique rotational mechanism. This design features an eccentric rotor that creates a turbulent mixing action, effectively disintegrating the fibers while minimizing energy consumption. The continuous and uniform distribution of material within the pulper ensures that the pulp is evenly processed, leading to higher-quality output.

One of the standout features of eccentric pulpers is their ability to operate at lower energy levels compared to conventional pulpers. The design allows for efficient input of power, reducing operational costs and lowering the environmental footprint. Eccentric pulpers are capable of handling a variety of raw materials, including mixed waste paper, newsprint, and even tougher fibers. This versatility makes them an essential tool for mills looking to diversify their feedstock and optimize recycling processes.

The adaptability of eccentric pulpers makes them suitable for various production scenarios. Whether a mill is focusing on high-quality grades of paper or processing mixed waste materials, these pulpers can accommodate the needs effectively.

Email: whiteboardpapermachine@gmail.com