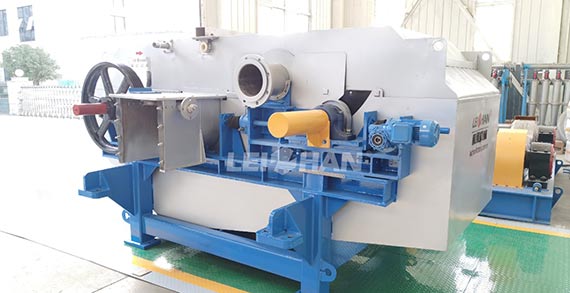

High-speed Stock Washer for Making Paper Pulp

The High-speed Stock Washer uses the principles of centrifugal force and fluid dynamics to separate the pulp into fiber and water through a high-speed rotating rotor. In this process, impurities and waste in the pulp are strongly impacted and separated. After being removed by the slag discharge system, the cleaned pulp flows out through the High-speed Stock Washer outlet. This process effectively reduces the residual pollutants in the pulp and provides high-quality raw materials for subsequent paper production.

In the entire paper production process, High-speed Stock Washers are usually located at the rear end of the pulping section, followed by pulping machines, separators and other equipment. After the initial pulping, the pulp enters the High-speed Stock Washer, and after cleaning, it flows to the subsequent fine screening and bleaching equipment. Its efficient cleaning function can not only greatly improve the quality of pulp, but also extend the service life of subsequent equipment, providing a guarantee for the stable operation of the entire production line.

Choosing an efficient and reliable high-speed pulp washer is the key to ensuring product quality and corporate competitiveness. If you want to know more information, please send me an email and we will send you more details.

Email: whiteboardpapermachine@gmail.com